Cross-section Microscopy Analysis of Exterior Paints: Secretary's Office (Block 17, Building 12), Williamsburg, VirginiaCross-section Microscopy Analysis Report: Secretary's Office Exterior (Block 17, Building 12)

Colonial Williamsburg Foundation Library Research Report Series - 1751

Colonial Williamsburg Foundation Library

Williamsburg, Virginia

2013

CROSS-SECTION MICROSCOPY ANALYSIS REPORT

SECRETARY'S OFFICE EXTERIOR

Block 17, Building 12

Washes on South Elevation Brick

COLONIAL WILLIAMSBURG FOUNDATION

WILLIAMSBURG, VIRGINIA

Secretary's Office, south elevation. During masonry repairs to the pediment (Travers, July 2012)

Secretary's Office, south elevation. During masonry repairs to the pediment (Travers, July 2012)

| Structure: | Secretary's Office, Block 17, Building 12; colored washes on brick, south elevation |

|---|---|

| Requested by: | Edward Chappell, Roberts Director of Architectural and Archaeological Research; and Matt Webster, Director of Historic Architectural Resources |

| Analyzed by: | Kirsten Travers, Paint Analyst, Department of Architectural and Archaeological Research |

| Consulted: | Susan L. Buck, PhD., Conservator and Paint Analyst, Williamsburg, Virginia |

| Date submitted: | July 27, 2012 |

Purpose:

The purpose of this investigation was to use cross-section microscopy techniques to examine and characterize the colored wash residues found on the brick frontispiece and field brickwork of the Secretary's Office by Ray Cannetti (mason). These joints are believed to be first period (Cannetti, personal comment to the author, July 2012).

Description/History1:

The Secretary's Office (also known as the Public Records Office), is a hip-roofed, one-story brick building that was erected in 1747 for the preservation of the public records in the colony. The need for such a structure was instigated by a fire which destroyed many records held in the adjacent Capitol Building on January 30, 1747.

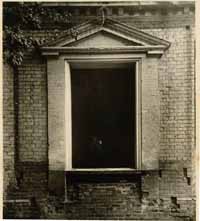

The building is raised in Flemish bond with glazed headers, and the south entrance doorway is pedimented with rubbed and gauged brick. This doorway is very similar to the main doorway of the Carter's Grove Plantation house. An archival photograph included in the architectural report shows that the brick facade was painted a light color at the time of the restoration.

Doorway of the Public Records Office, before restoration, 1939 [taken from the Architectural Report].

Doorway of the Public Records Office, before restoration, 1939 [taken from the Architectural Report].

Previous finishes research:

In 1989, Frank S. Welsh analyzed one sample from the north cornice fascia. He concluded that the first generation was a red-brown oil paint (Welsh 1989).

Procedures:

On July 24, 2012, Kirsten Travers collected five paint samples (SO 1 — SO 5 ), from the south elevation, which was undergoing repairs to the pediment. She was accompanied on-site by Ray Cannetti, mason. A monocular 30x microscope was used to examine the painted surfaces and determine the most appropriate areas for sampling. A microscalpel was used to remove the samples, which were labeled and stored in small individual Ziploc bags for transport. All samples were given the prefix "SO" and numbered according to the order in which they were collected.

In the laboratory, the samples were examined with a stereomicroscope under low power magnification (5x to 50x), to identify those that contained the most intact paint evidence and would therefore be the best candidates for cross-section microscopy. Uncast sample portions were retained for future examination and analysis. The best candidates were cast in resin cubes and sanded and polished to expose the cross-section surfaces for microscopic examination.

Once cast, the cross-section samples were examined and digitally photographed in reflected visible and ultraviolet light conditions at 100x to 400x magnifications. By comparing the resulting photomicrographs, finish generations could be interpreted based on physical characteristics such as color, texture, thickness, presence of dirt layers and extent of surface deterioration. The most informative photomicrographs and their corresponding annotations, as well as comments from the author, are contained in the body of this report.

Results:

In the following report, all three samples are shown and interpreted. The paint layers in each photomicrograph have been annotated according to "generation". For instance, a primer, paint layer, and varnish layer may represent one finish generation, and are all given the same number, but distinguished with letters a, b, c, d, etc., according to the order in which they were applied. All results are interpreted in the conclusion.

Sample locations

Sample SO 1:

Sample SO 1:

Left (west) side of pediment, bottom (cyma reversa) trim, 1st and 2nd bricks to left (west) side of apex. Red-brown wash residues on

brick surfaces.

Sample SO 2:

Sample SO 2:

Mortar joint in center of tympanum. Red-brown wash on mortar.

Sample SO 3:

Sample SO 3:

Mortar joint at interface of top edge of tympanum and left (west) side of pediment, bottom edge of bottom (cyma reversa) trim. Red-brown washes on mortar.

Sample SO 4:

Sample SO 4:

Brick course just under the entablature, mortar joint under the third brick left (west) of the pilaster. Red-brown and yellow washes on

mortar.

Sample SO 5:

Sample SO 5:

Mortar joint between left (west) pilaster and brick wall. 20" down from pediment entablature. Same wash residues seen as SO 4.

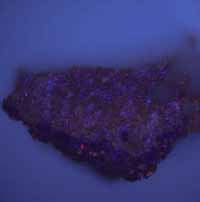

SO 1: Left (west) side of pediment, bottom (cyma reversa) trim, 1st and 2nd bricks to left (west) side of apex. Red-brown wash residues on brick surfaces.

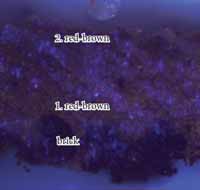

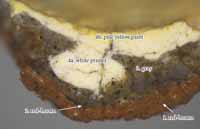

During sampling, it was noted that the brick substrate was light orange in color and somewhat powdery. In the above photomicrograph, the brick substrate is visible at the bottom of the sample as a bright orange-red colored-material with large particles of aggregate. The surface of the brick appears rather worn and uneven, so it is possible that the first generation red-brown was applied after the brick was exposed for some time.

Generation 1 is a reddish-brown colored wash.

Generation 2 is a reddish-brown colored wash, which is much more red/orange in color than generation 1.

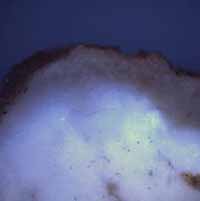

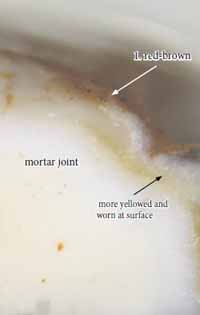

SO 2: Mortar joint in center of tympanum. Red-brown wash on mortar.

SO 2, visible light, 40x (enlarged)

SO 2, visible light, 40x (enlarged)

SO 2, UV light, 40x (enlarged)

SO 2, UV light, 40x (enlarged)

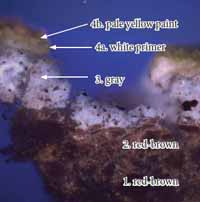

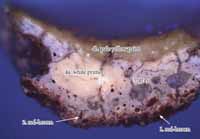

The surface of the joint is uneven, yellowed and has a dim autofluorescence in UV light, which suggests that the joint was already exposed for some time before the first generation red-brown wash was applied. This red-brown wash is very thin and fragmented in the cross-section, but it is the same as that found in sample SO 1 (previous page).

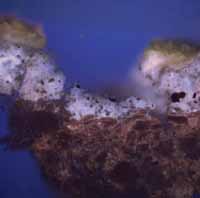

SO 3: Mortar joint at interface of top edge of tympanum and left (west) side of pediment, bottom edge of bottom (cyma reversa) trim. Red-brown washes on mortar.

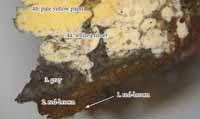

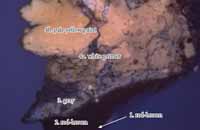

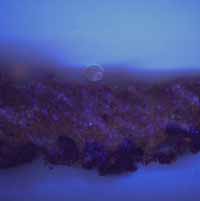

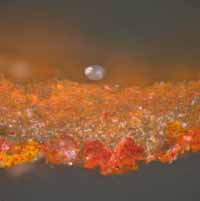

Samples SO 3, SO 4, and SO 5 contain the same paint stratigraphies (see following pages). Four coating generations were identified. Like sample SO 2, the mortar joint in sample SO 3 is yellowed and worn at the surface, suggesting it was exposed for some time before the first generation red-brown was applied. This red-brown is the same as that found in samples SO 1-2, previous pages). Generation 2 is another red-brown paint, the same as that seen in sample SO 1).

Generation 3 is a coarsely ground gray paint. This contains black particles of various sizes in a grayish, translucent matrix that has a bright autofluorescence in UV light, suggestive of a resinous material. Generation 4 is composed of a white primer and a pale yellow paint. These coatings are opaque and have a dim autofluorescence in UV light, suggestive of an oil-based paint.

SO 4: Brick course just under the entablature, mortar joint under the third brick left (west) of the pilaster. Red-brown and yellow washes on mortar.

The paints in sample SO 4 are very disrupted and soiled, but this paint history is the same as that seen in sample SO 3 (previous page), taken from the tympanum, and sample SO 5 (next page), taken from the mortar joint between the pilaster and wall.

SO 5: Mortar joint between left (west) pilaster and brick wall. 20" down from pediment entablature. Same wash residues seen as SO 4.

Conclusions:

Four coating generations were identified on the brick exterior of the Secretary's Office. These do not appear to be first period finishes, as the bricks and mortar joints beneath the paints show evidence of exposure and wear before the extant coatings were applied. However, this does not suggest that the exterior of the Secretary's Office was not color-washed originally, only that evidence for these washes might have been lost through exterior exposure and wear. The most recent coating (generation 4) appears to have been the presentation surface at the time of the restoration (1939), so the preceding generations could be 19th-century, or even late 18th-century finishes.

Generations 1 and 2 are reddish-brown coatings. These are very powdery and loosely bound, which could result from extended periods of exposure and wear. Binding media analysis was not carried out, but these are most likely lime-based washes, although this would need to be confirmed with fluorochrome staining and/or instrumental techniques such as Fourier-transform infrared spectroscopy (FTIR) or gas-chromatography-mass spectrometry (GC-MS). Previous analyses of exterior brick washes on other Virginian 18th and early 19th-century buildings has determined that these coatings sometimes contain organic additives such as carbohydrates, oils, or proteins (Travers 2012, and Buck, Lounsbury, and Maul 2003).

Generation 3 is a gray coating, which appears to consist of black pigment particles in a resinous medium.

Generation 4 appears to be an oil-based white primer and pale yellow paint. The archival image of the south facade doorway (page 2), suggests that this could be the coating that was in existence when the building was restored in 1939.

Footnotes

References:

- Buck, S., C. Lounsbury and A. Maul. 2003. "Color Washes and Penciling on Bricks and Mortar Joints in the Chesapeake." Report for the Colonial Williamsburg Foundation, Architectural and Archaeological Research Department.

- Kocher, L. 1945. "Public Records Office Architectural Report, Block 17." Unpublished report for the Colonial Williamsburg Foundation.

- Travers, K. June 2012. "Cross-Section Microscopy Analysis Report: Margaret Hunter Shop, Block 17, Building 9." Unpublished report for the Colonial Williamsburg Foundation, Architectural and Archaeological Research Department.

- Welsh, F. S. 1989. "Microscopical Analysis to Determine and Evaluate the Nature and Colors of the Original Surface Coatings: Public Records Office." Unpublished report for the Colonial Williamsburg Foundation, Architectural and Archaeological Research Department.

Appendix A: Procedures

Sample Preparation:

The samples were cast in mini-cubes of Extec Polyester Clear Resin (methyl methacrylate monomer), polymerized with the recommended amount of methyl ethyl ketone peroxide catalyst. The resin was allowed to cure for 24 hours under ambient light. After cure, the individual cubes were removed from the casting tray and sanded down using a rotary sander with grits ranging from 200 — 600 to expose the cross-section surface. The samples were then dry polished with silica-embedded Micro-mesh Inc. cloths with grits ranging from 1500 to 12,000, lending the final cross-section surface a glassy-smooth finish.

Microscopy and Documentation:

The cross-section samples were examined using a Nikon Eclipse 80i microscope equipped with an EXFO X-cite 120 fluorescence illumination system fiberoptic halogen light source. Samples were examined and photographed under visible and ultraviolet light conditions (excitation 330-380 nm, barrier filter 420nm), at 40-400x magnifications. Digital images were captured using a Spot Flex digital camera with Spot Advance (version 4.6) software. All images were recorded as 12.6 MB tiff files and stored on a hard drive in a folder titled "Secretary's Office" on Susan Buck's laboratory computer. A separate set of images are stored on the CWF digital database, accompanied by the appropriate metadata and a digital version of the final report.

Information Provided by Visible and Ultraviolet Light Microscopy:

When examining paint cross-sections under reflected visible and ultraviolet light conditions, a number of physical characteristics can be observed to assist with the interpretation of a paint stratigraphy. These include the number and color of layers applied to a substrate, the thickness or surface texture of layers, and pigment particle size and distribution within the paint film. Relative time periods for coatings can sometimes be assigned at this stage: for instance, pre-industrial-era paints were hand ground, lending them a coarse, uneven surface texture with large pigment particles that vary in size and shape. By contrast, more "modern", industrially-prepared paints have smoother, even surfaces and machine-ground pigment particles of a consistent size and shape. Furthermore, he presence of cracks, dirt layers, or biological growth between layers can indicate presentation surfaces and/or coatings that were left exposed for an extended period of time.

Under UV light conditions, the presence and type of autofluorescence colors can distinguish sealants, clear coatings, and binding media, from darker dirt or paint layers within the stratigraphy. For instance, shellacs exhibit a distinct orange-colored autofluorescence, while natural resins (such as dammar and mastic), typically fluoresce a bright white color. Oil media tends to quench autofluorescence, while most modern, synthetic paint formulations (such as latex) exhibit no fluorescence at all. Some pigments, such as verdigris, madder, and zinc white, have distinct fluorescence characteristics, as well. UV light microscopy is critical to help distinguish otherwise identical layers often found in architectural samples— such as successive varnishes, or multiple layers of unpigmented (white) limewash.

Appendix B. Sampling memorandum

Cc: Matt Webster

From: Kirsten Travers

Date: July 24, 2012

Re: Secretary's Office Façade, exterior paint samples

Today I collected five samples (SO 1-5) from the façade of the Secretary's Office, where residues of colored washes were found on the brick and mortar joints by Ray Cannetti, mason, during repair work on the pediment. I was accompanied on-site by Ray Cannetti (mason) and William Neff (brickmaker and interpreter).

- SO 1 Left (west) side of pediment, bottom (cyma reversa) trim, 1st and 2nd bricks to left (west) side of apex. Red-brown wash residues on brick surfaces.

- SO 2 Mortar joint in center of tympanum. Red-brown wash on mortar.

- SO 3 Mortar joint at interface of top edge of tympanum and left (west) side of pediment, bottom edge of bottom (cyma reversa) trim. Red-brown washes on mortar.

- SO 4 Brick course just under the entablature, mortar joint under the third brick left (west) of the pilaster. Red-brown and yellow washes on mortar.

- SO 5 Mortar joint between left (west) pilaster and brick wall. 20" down from pediment entablature. Same wash residues seen as SO 4.